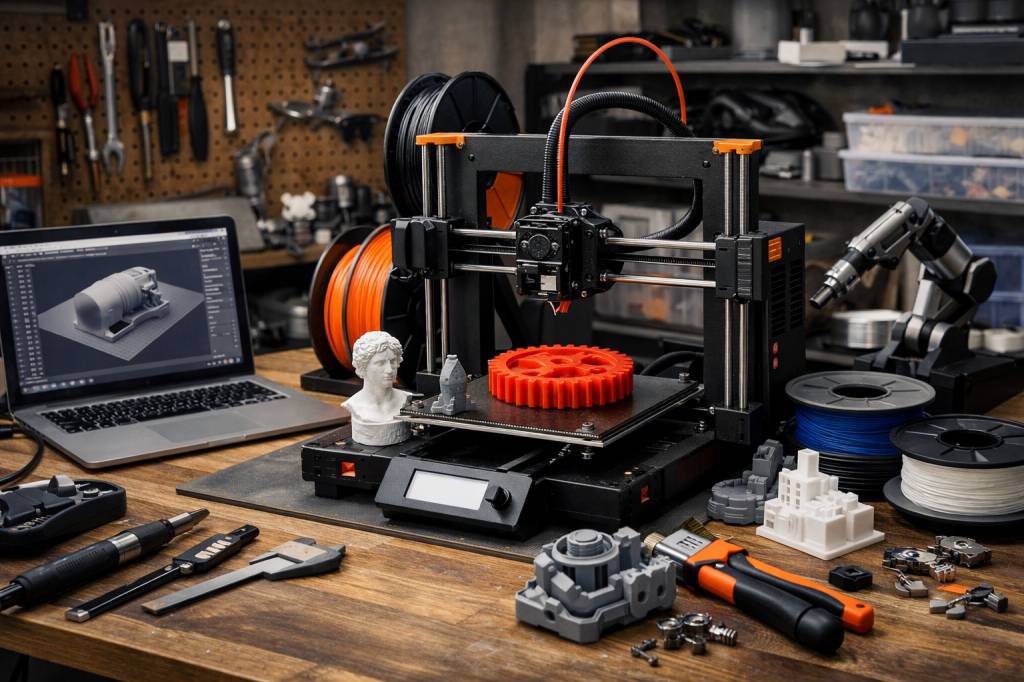

3D printing used to be that odd machine hidden in a university lab, spitting out fragile plastic prototypes at glacial speed. Today, it’s on factory floors, in garages, on kitchen tables – and increasingly, inside strategic roadmaps of big manufacturers.

Beyond the hype, additive manufacturing (its more formal name) is quietly changing how we design, produce, repair and customize objects. From aerospace parts to cosplay helmets, the logic of “print what you need, when you need it” is starting to bite into the traditional idea of manufacturing.

From prototyping tool to production method

For years, 3D printing was mostly a prototyping tool. You designed a piece, printed a rough version, checked shape and ergonomics, then moved to “real” production with molds and machining. That’s still a massive use case, but we’re now in another phase: printing final parts.

Why is that happening now?

- Speed has improved: FDM and resin printers that used to take 24 hours now do the job in 4–6 hours for medium parts.

- Precision is up: Layer heights of 0.05 mm are common on consumer resin printers, with surprisingly smooth surfaces.

- Costs are down: Entry-level printers under €300 can produce parts good enough for functional use.

Industries that used to depend on expensive tooling have a lot to gain. A custom aluminum mold for injection molding can easily cost €10,000–€50,000 and takes weeks. With 3D printing, you skip that step entirely for small to medium runs.

Think of 3D printing not as a cheaper way to make the same things, but as a different way to think about what’s worth making at all: ultra-small batches, one-off parts, on-demand spares and designs that would be impossible to mill from a solid block.

New materials, new possibilities

When people picture 3D printing, they often think “colorful plastic toys.” That’s now only a tiny slice of the story. The material ecosystem has exploded.

For hobbyists and small businesses, you now have:

- PLA: Easy to print, biodegradable under industrial conditions, perfect for decorative objects, prototypes, jigs.

- PETG: More temperature-resistant, good for outdoor use and functional parts that need some flexibility.

- ABS / ASA: Strong and heat-resistant, often used for enclosures, automotive parts, and outdoor pieces (ASA resists UV better).

- Flexible filaments (TPU/TPE): For phone cases, gaskets, custom soles, vibration dampers.

- Composites: PLA or nylon reinforced with carbon fiber, glass fiber or Kevlar for very rigid, strong parts.

- Resins: From ultra-detailed (for miniatures) to engineering resins with high impact, high temperature or flexible properties.

On the industrial side, metal 3D printing is moving from experiment to real production. Aerospace giants are already flying printed titanium brackets and fuel nozzles. In 2015, GE’s LEAP engine introduced a 3D-printed fuel nozzle that replaced 20 separate parts with a single printed component – lighter, stronger, and easier to assemble.

All of this changes the design mindset. You’re no longer limited by “can I machine this?” but by “can I model it and can my printer handle the material?” That’s a big shift.

How 3D printing is reshaping factories

We’re not (yet) at the point where every product rolls out of a giant 3D printer. But the places where 3D printing has quietly invaded manufacturing are very telling.

1. Tooling and jigs

In many factories, 3D printers are first used to create small tools, assembly jigs and fixtures. These are often:

- Custom to each workbench or worker

- Replaced frequently due to wear

- Too niche to justify traditional tooling

A 3D-printed jig that used to be ordered externally for €300 can often be designed in-house and printed overnight for under €20 in material. Multiply that by dozens of tools and you’re looking at serious savings and more flexibility on the production line.

2. Spare parts on demand

Industrial machines fail. Often because of small plastic parts that are no longer manufactured. Instead of shutting down a production line for days while a replacement is sourced (or retrofitted), some factories now print those parts in-house or via local service providers.

The impact:

- Less downtime: For high-throughput plants, every hour counts.

- Less inventory: You store files instead of boxes of spares.

- Longer machine lifetimes: You’re not at the mercy of discontinued parts.

3. Mass customization

3D printing shines where “every unit is different.” Hearing aids are a classic example: almost all custom hearing aid shells are now 3D printed based on scans of the wearer’s ear canal. Dental aligners follow a similar logic with printed molds.

The same pattern applies elsewhere:

- Custom grips and handles adapted to a worker’s hand

- Bike components tailored to a rider’s morphology

- One-off ergonomic keyboard cases for specific workflows

Traditional methods hate variation. Additive manufacturing doesn’t care if each file is unique, as long as the printer time and material are there.

The rise of the home maker and “hyper-personal” DIY

At home, 3D printing has unlocked a new kind of DIY: less “hammer and nails,” more “CAD and slicer.” Instead of adapting to what’s available in stores, you design the object that fits your use case exactly.

Typical scenarios you’ll recognize if you’ve spent 10 minutes on Thingiverse or Printables:

- A cable organizer that fits that specific gap behind your desk.

- A phone stand designed for your tablet + keyboard combo, at your preferred angle.

- A replacement knob for a washing machine whose original part is backordered for months.

- Custom mounts for smart home sensors, LEDs or routers.

- Game controller mods, VR headset accessories, camera rigs for content creators.

Notice the pattern? These are often small, unglamorous pieces. But they stick because they solve hyper-specific problems. No mass-market brand will ever design a bracket for your exact wall, cable, and router model. You can.

The barrier to entry is also dropping fast:

- Printers under €300 are now reliable enough for daily use.

- Free CAD tools (Fusion 360 hobby license, Onshape, FreeCAD, Tinkercad) make modeling accessible.

- Communities share ready-to-print files and step-by-step guides.

The DIY profile itself is evolving. 3D printing attracts people who don’t necessarily identify as “handy” but are comfortable with software, iteration and troubleshooting. It’s a different skill set, but the same satisfaction: “I made this, and it works.”

Repair, sustainability and the right-to-fix

3D printing is also impacting a more political space: the right to repair.

When a small plastic clip breaks on a €700 appliance, you can:

- Pay for an expensive official spare (if it exists)

- Throw away the device and buy a new one

- Or… model and print the part

Communities are already sharing libraries of replacement parts for appliances, strollers, garden tools, and even cars. It’s not a perfect solution—material properties and safety constraints do matter—but it extends the life of many objects at near-zero cost.

Environmentally, there is nuance:

- Printing locally reduces shipping and overproduction.

- But plastics like PLA, while “bio-based,” are not automatically compostable at home.

- Failed prints and constant “tinkering” can generate waste if you’re not intentional.

Used responsibly, 3D printing can be an ally of a more circular economy: repair instead of replace, adapt instead of discard, produce on demand instead of overstocking.

Limits and hard truths (because no, it won’t replace everything)

It’s tempting to see 3D printing as the Swiss army knife of manufacturing. Reality is more nuanced.

1. Speed and scale

For large volumes of identical products, injection molding still wins on speed and price, hands down. Printing 10,000 identical keychains will almost always be slower and more expensive than molding them. 3D printing shines for small batches, complex geometries or when each piece is different.

2. Surface finish and strength

Layer lines are real. For many functional parts, that’s not an issue. For consumer products straight off the machine, post-processing (sanding, painting, vapor smoothing) is often necessary. Mechanical properties also vary strongly by orientation: a part printed “standing up” might be weaker along layer lines than across them.

3. Learning curve

Despite massive progress, 3D printing is not plug-and-play magic.

- You need to learn basic 3D design or at least how to tweak existing models.

- You’ll wrestle with bed adhesion, warping, supports, clogged nozzles.

- Calibration and maintenance are part of the game.

For many people, that learning curve is a feature, not a bug. But you should go in with realistic expectations: your first week will include both satisfying prints and impressive spaghetti failures.

4. Intellectual property

Printing replacement parts or fan-made versions of branded products raises legal and ethical questions. Some manufacturers are starting to publish official 3D models of basic parts; others take a much more closed approach. The legal framework is still catching up with what’s technically possible.

Want to start? A pragmatic roadmap

If you’re thinking “maybe 3D printing could help my projects or my business,” here’s a grounded way to explore it without getting lost in the gadget side of things.

1. Define one or two concrete use cases

- At home: organizing cables, custom mounts, repairing a broken part.

- In a small business: product mockups, packaging inserts, custom fixtures.

- In a workshop: tool holders, jigs, safety guards, prototypes.

Having real problems to solve will guide every other choice: printer type, material, software.

2. Start “good enough,” not “perfect”

Unless you’re working in dentistry or aerospace, you probably don’t need an industrial machine. A well-known consumer FDM printer in the €250–€600 range is usually enough to:

- Validate your use cases

- Understand your real constraints (size, precision, material)

- Build internal skills before scaling up

3. Use existing designs before going full CAD warrior

Platforms like Thingiverse, Printables or MyMiniFactory are goldmines. Instead of designing everything from scratch:

- Print existing models that match your needs.

- Modify them slightly using simple tools or parametric options.

- Observe how others solve typical problems (clips, hinges, threads).

Once you hit the limits of “remix culture,” you’ll have the motivation and context to learn real 3D design.

4. Think workflow, not just machine

A 3D printer is only one piece of the puzzle. Your actual workflow will look like this:

- Model or download →

- Slice (prepare the file for printing) →

- Print →

- Post-process →

- Test in real use →

- Iterate

Each step is an opportunity to improve: better orientation for strength, smarter supports, different infill patterns, etc. The power of 3D printing is precisely in that rapid loop of iteration.

What’s coming next for 3D printing and why it matters

Looking a few years ahead, several trends are worth watching if you care about manufacturing, DIY or simply how objects are made.

1. Hybrid machines and processes

We’re already seeing machines that combine additive and subtractive processes: they print a part, then machine critical surfaces for perfect tolerances. For many industrial applications, this hybrid approach may become the default: the design freedom of 3D printing plus the precision of CNC.

2. Smarter, more autonomous printers

AI is starting to slip into the workflow:

- Automatic detection of failing prints via cameras.

- Real-time adjustment of parameters to avoid warping and stringing.

- Generative design: software suggesting organic-looking geometries optimized for weight and strength, often impractical to make without 3D printing.

In other words, machines that don’t just execute but also help you design and secure successful prints.

3. Distributed micro-factories

E-commerce and 3D printing are a natural combination. Instead of shipping physical stock worldwide, some brands will ship files to certified local print hubs or even to customers’ homes. That raises plenty of questions—quality control, IP, support—but the economic logic is compelling for certain products.

Imagine ordering a spare part from a brand and receiving a download link plus a suggested material, instead of a package traveling 5,000 km.

4. Everyday objects designed “additive-first”

We’re still in a transition period where many designs are optimized for molding or machining, then adapted for printing. As new generations of engineers and designers grow up with 3D printing as a default tool, we’ll see more objects that could only exist thanks to additive:

- Lightweight lattice structures impossible to mill.

- Integrated hinges, clips and channels printed as one piece.

- Products assembled from fewer parts because “the printer can do it.”

And that’s where the link between industrial manufacturing and DIY becomes particularly interesting: the same design principles, the same software, and often the same file formats are used in a garage and in a factory.

Whether you’re a maker, an entrepreneur or simply someone who likes to fix things instead of throwing them away, 3D printing is no longer a gadget to watch from afar. It’s a practical tool that can already change the way you think about objects: not as static, predefined items, but as evolving solutions you can adapt, repair and redesign—layer by layer.